January 27, 2025

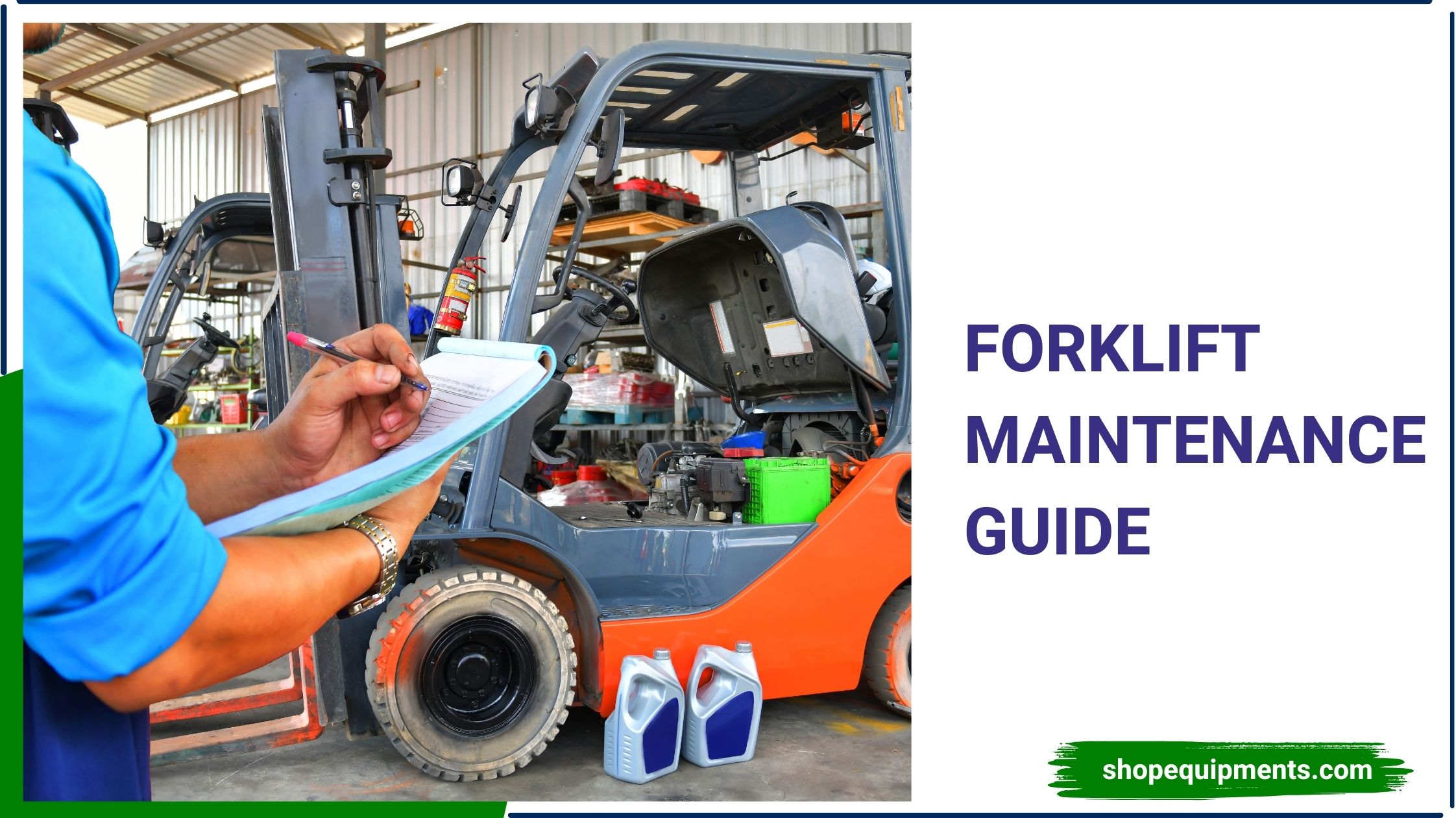

Forklift Maintenance Guide Avoid Costly Repairs

Forklifts are essential in warehouses, construction sites, and manufacturing units.

Proper maintenance not only extends their lifespan but also enhances workplace safety and reduces unexpected downtime.

This guide provides a structured approach to forklift maintenance, ensuring optimal performance and preventing costly repairs.

Why Forklift Maintenance Matters

Neglecting forklift maintenance can lead to severe consequences, including:

- Increased repair costs due to component failures.

- Reduced efficiency from sluggish or malfunctioning parts.

- Workplace accidents caused by mechanical faults.

- Regulatory penalties for non-compliance with safety standards.

Regular maintenance helps businesses stay compliant, reduce expenses, and maximize productivity.

Daily Forklift Maintenance Checklist

Performing a daily inspection before operation prevents potential hazards. Operators should check:

- Tires and Wheels – Look for cracks, wear, and proper inflation.

- Brakes and Steering – Ensure smooth operation without resistance.

- Hydraulic System – Inspect for leaks and fluid levels.

- Forks and Mast – Check alignment and structural integrity.

- Battery or Fuel Levels – Ensure sufficient charge or fuel.

- Warning Lights and Horn – Confirm they are functional.

Weekly Forklift Maintenance Tasks

In addition to daily checks, a more in-depth inspection should be conducted every week:

- Lubrication of moving parts to reduce friction.

- Inspection of hoses and belts for wear and tear.

- Testing of emergency shut-off systems.

- Checking coolant and oil levels to prevent overheating.

Monthly Forklift Maintenance Routine

A monthly maintenance schedule should include:

- Brake System Inspection – Ensure pads and fluid are in good condition.

- Battery Health Check – Clean terminals and check voltage levels.

- Chain and Mast Lubrication – Prevent rust and friction damage.

- Alignment of forks – Misaligned forks can cause uneven load distribution.

- Emission Testing – For gas and diesel forklifts, ensuring proper exhaust function is essential.

Seasonal Maintenance Considerations

Environmental factors can impact forklift performance. Adjust maintenance based on seasonal conditions:

- Winter Maintenance:

- Use winter-grade hydraulic oil.

- Inspect heaters and defrosters in cabin models.

- Check battery performance, as cold weather affects charging.

- Summer Maintenance:

- Monitor coolant levels to prevent overheating.

- Inspect tires for excessive wear due to hot surfaces.

- Ensure ventilation systems are functioning properly.

Common Forklift Issues and Solutions

1. Starting Problems

- Possible Causes: Dead battery, fuel issues, or electrical faults.

- Solution: Check the battery charge, fuel levels, and electrical connections.

2. Unusual Noises

- Possible Causes: Loose components, low lubrication, or worn-out bearings.

- Solution: Tighten loose parts and apply proper lubrication.

3. Hydraulic System Leaks

- Possible Causes: Damaged hoses or worn-out seals.

- Solution: Replace faulty hoses and check seals for integrity.

4. Fork Misalignment

- Possible Causes: Improper handling or mechanical wear.

- Solution: Realign forks and ensure mast components are in good condition.

Forklift Battery Maintenance (For Electric Models)

Electric forklifts rely on battery health for performance. Proper maintenance includes:

- Charging after each shift to avoid deep discharges.

- Cleaning terminals to prevent corrosion.

- Checking electrolyte levels regularly.

- Storing batteries in a dry, cool area.

Preventive Maintenance Schedule

A structured preventive maintenance plan minimizes unexpected failures. A general schedule includes:

| Maintenance Task | Frequency |

| Daily inspections | Before use |

| Lubrication of parts | Weekly |

| Brake system check | Monthly |

| Battery health check | Monthly |

| Chain and mast lubrication | Monthly |

| Seasonal adjustments | Quarterly |

| Full mechanical review | Annually |

Best Practices for Forklift Maintenance

- Train Operators on Maintenance Procedures – Ensuring all users understand the importance of regular checks.

- Keep Maintenance Records – Track inspections and repairs for compliance.

- Use Manufacturer-Approved Parts – This ensures compatibility and reliability.

- Schedule Professional Inspections – A certified technician should assess forklifts annually.

- Address Issues Immediately – Delaying minor repairs can lead to expensive breakdowns.

Conclusion

Effective forklift maintenance is crucial for safety, efficiency, and cost reduction.

Following a structured maintenance plan helps businesses minimize downtime and extend the lifespan of their equipment.

Implementing regular inspections, preventive maintenance, and timely repairs ensures forklifts remain in peak working condition.

By prioritizing maintenance, companies can prevent costly breakdowns and keep their operations running smoothly.